What makes BECCA different? Our Patented BECCA Consumables!

ReNu Our Newest Consumable

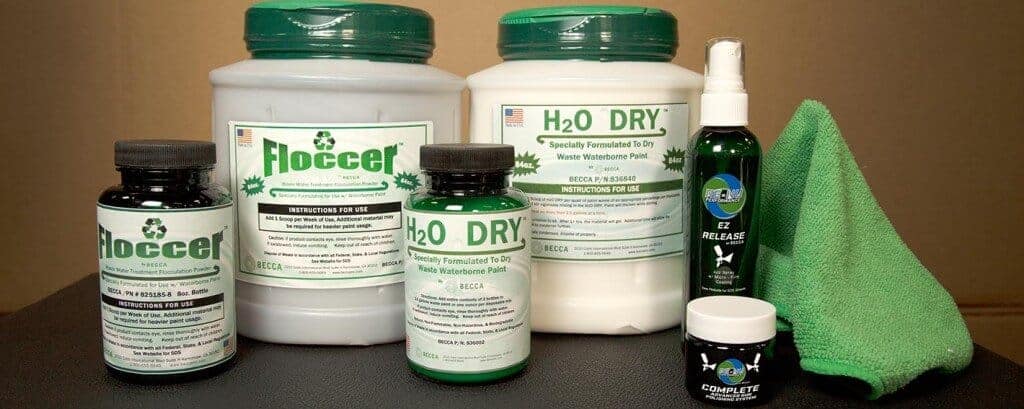

BECCA’s line of consumables is important for the implementation of the BECCA 3P System. Our consumables are created to make cleaning paint spray guns more effective, efficient, as well as reducing hazardous waste in body shops.

RE-NU, BECCA’s newest consumable, is our solution for a polishing process on paint spray guns. A highly effective polish for spray guns, restoring paint guns to a like-new finish. Thus providing a great foundation for implementing the BECCA 3P System. Re-Nu is highly recommended for use on spray guns prior to using our Water Wave solution for waterborne paint guns. ReNu successfully removes any film that exists on spray guns from prior use allowing for great success with Water Wave, therefore making future cleaning more effective.

|

|

Re-Nu: [more information on RENU]

|

Water Wave  Waterborne Cleaning Solution

Waterborne Cleaning Solution

![]() This is BECCA’s waterborne cleaning solution. Water Wave creates a microfilm coating on the spray gun, as a result reducing paints’ ability to stick to the metal. (Note: this does not affect the performance of spray guns or end up on paint finish.) Many waterborne cleaning solutions contain solvents. Solvents in waterborne cleaning solutions will cause the waterborne paint to adhere to the surface of the spray gun and is rather difficult to remove. Water Wave contains no solvents, in addition to the microfilm coating, Water Wave reduces the ability of paint to adhere to the paint spray gun. Solvents are also damaging to the plastic components on waterborne spray guns. Water can be harsh on the spray gun surface as well. Water Wave is a PH-neutral cleaner therefore it will not leave a residue that leads to corrosion.

This is BECCA’s waterborne cleaning solution. Water Wave creates a microfilm coating on the spray gun, as a result reducing paints’ ability to stick to the metal. (Note: this does not affect the performance of spray guns or end up on paint finish.) Many waterborne cleaning solutions contain solvents. Solvents in waterborne cleaning solutions will cause the waterborne paint to adhere to the surface of the spray gun and is rather difficult to remove. Water Wave contains no solvents, in addition to the microfilm coating, Water Wave reduces the ability of paint to adhere to the paint spray gun. Solvents are also damaging to the plastic components on waterborne spray guns. Water can be harsh on the spray gun surface as well. Water Wave is a PH-neutral cleaner therefore it will not leave a residue that leads to corrosion.

The issue with many waterborne cleaning solutions is the smell. Water-based cleaning solutions create great homes for bacteria, which lead to smelly cleaning solutions. At BECCA, we have added antimicrobial properties to Water Wave to ensure it won’t smell like a sewer after two weeks, lasting more than 14 weeks longer than any other cleaning solution.

Water Wave: [more information on WaterWave]

FLOCCER WASTE MANAGEMENT

|

FLOCCER a waste management process added to waterborne waste from paint gun cleaners. Once added to the waterborne waste and agitated the FLOCCER causes paint to coagulate. This allows the two-stage micron filter to separate paint waste from the water, resulting in clean water for reuse. As a result, the remaining paint waste can be thrown away in the regular waste stream.

Water is not an expensive cost to auto body repair shops. FLOCCER helps shops save money they spent on the additives in the water, such as the Water Wave cleaning solution. Waterwave is able to pass through the filters in this process and results in shops saving in their use of cleaning solutions that are added to water.

Floccer: [more information on FLOCCER]

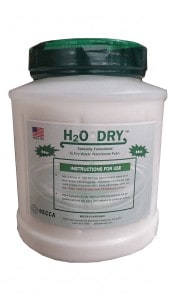

H20 DRY Waste Management

84 oz.

Adding H2O DRY to waste paint results in dried and hardened waste. Adding H20 DRY to waterborne waste (which is classified as hazardous material in liquid form), transforms waste into dry and non-flammable substance, thus allowing for disposal as regular waste. The H2O Dry absorbent is a cost-effective solution for paint shops needing regular disposal of waterborne waste.

Once absorbents have been added to waste paint solutions and the hardening process is complete a hazardous waste test should be conducted to ensure it passes requirements for the TCLP (test for heavy metals), dryness, and flammability.

H2O Dry: [more information on H2O DRY]