It Is Time To Evaluate The Process

Inefficiencies in production at auto body repair shops can often go unobserved and unnoticed, slowly draining a significant portion of your company’s profits. Have you been noticing these issues in your shop?

- Re-do’s and Repairs, Heavy Films, Nib and Buffing

- Long Dry Times

- Waste Removal/Disposal

Re-do’s and Repairs, Heavy Films, Nib and Buffing

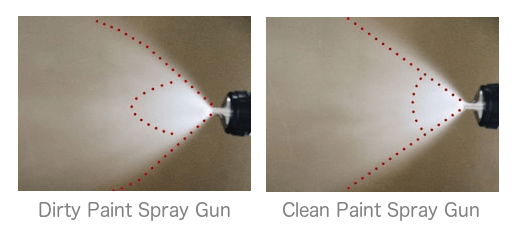

Neglected spray gun cleaning processes can pose a great threat to the success of body shops. Paint builds up in fluid/air passageways which disrupting the flow air and fluids. A result of improperly cleaned paint spray guns. Paint build-up in fluid lines causes contamination and tiger stripping resulting in nib and buffing or possibly even re-do’s. Paint build up in fluid passageways also causes the pattern of the spray gun to shrink. This requires the painter to spend more time painting vehicles thus using more material to achieve proper coverage. Extra time and materials result in the increased cost of vehicle repair per unit in body shops, as well as cost resulting from longer dry times.

Long Dry Times

Long dry times result in vehicles sitting in paint booths drive down shop productivity. Many auto body repair shops do not have the appropriate drying system in their paint booths. Many shops having none at all. Thus causing additional time and money used to repair the damage that many air movement systems create or long periods of waiting on paint to dry. Many air movement systems fail to utilize proper air movement and therefore create high-velocity air movement hoping faster air will result in faster dry times. Though, the direct contact of high-velocity air on wet surfaces may dry the surface faster the rest of the surfaces will take longer, especially bumpers or door handles on vehicles. High-velocity air movement increases chances for nib and buffing do to debris getting stirred in the paint booth.

Waste Removal/Disposal

Hazardous waste, as most shop owners know, is an expensive by-product of auto body repair shops. Waste must be stored and handled according to government-set regulations for body shops then disposed of according to each state’s laws and regulations. This becomes an expensive process if dealt with inefficiently. Hazardous 55-gallon waste drums can cost anywhere from $200 to $1000+ for hazardous waste disposal services, depending on what state your business is located in. A misconception that commonly occurs is the treatment for waterborne waste. Waterborne paint can be free of solvents, however, it is still considered hazardous waste until proven different. Therefore, proper hazardous waste treatment is required, even for waterborne paint waste.

“Slow Dry Times – An Unavoidable Cost? They don’t have to be”