|

What Painters Have: |

What Painters Need: |

|

|

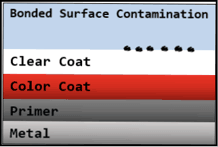

Contamination

Contamination is a common issue found with air drying systems for paint booths. Many of these systems have good intent on speeding up the paint process, however this often is the cause more issues. There are many ways Contamination is ending up on painted surfaces, which results in additional steps such as nib and buffing. This slows down flow in the paint shop. There are multiple ways air drying systems stir contamination in the booth.

Contamination is a common issue found with air drying systems for paint booths. Many of these systems have good intent on speeding up the paint process, however this often is the cause more issues. There are many ways Contamination is ending up on painted surfaces, which results in additional steps such as nib and buffing. This slows down flow in the paint shop. There are multiple ways air drying systems stir contamination in the booth.

Drying Systems Stirring Contamination

- High velocity systems causing overspray to lift from the floor and walls.

- Moving fan blades inside the booth, generating a static charge, collecting overspray, and releasing when started

- Over spray collection on nozzles, released when turned on

- Lack of maintenance on mechanical systems causing vibration, displacing overspray

- Operator continually moving systems in and out of the booth

The ability to address these issues can speed up the painting process and quality of work leaving the booth. Resulting in less rework, thus creating a better flow of vehicles in paint shops. Contamination can be the thorn in a painter’s side, as it can come from multiple sources. Tackling the issue of air drying systems removes a source of contamination and results in faster dry times when applied appropriately.

The ability to address these issues can speed up the painting process and quality of work leaving the booth. Resulting in less rework, thus creating a better flow of vehicles in paint shops. Contamination can be the thorn in a painter’s side, as it can come from multiple sources. Tackling the issue of air drying systems removes a source of contamination and results in faster dry times when applied appropriately.

When air drying systems have not been applied appropriately painters often avoid using the systems due to the issues created regarding contamination. In looking for effective air drying systems there are several features to look for:

- Low Velocity Air

- Features Directly Addressing Contamination

- Systems requiring minimal adjustments

Low Velocity Air

Low velocity air movement prevents contamination from lifting off the floors, walls, and cracks and crevices of the vehicle, or any other source of contamination. When applied appropriately also prevents a boundary layer from forming around the surface of the vehicle. To learn more about the boundary layer refer to the article Key Factors to Air Drying Paint Effectively and Efficiently. Key Factors In Drying Paint

Low velocity air movement prevents contamination from lifting off the floors, walls, and cracks and crevices of the vehicle, or any other source of contamination. When applied appropriately also prevents a boundary layer from forming around the surface of the vehicle. To learn more about the boundary layer refer to the article Key Factors to Air Drying Paint Effectively and Efficiently. Key Factors In Drying Paint

Adjusting systems

Adjusting systems can be time consuming and tedious processes for painters. Therefore, systems that make adjustments tremendously easy and unnecessary for normal drying tasks allows painters to focus their time on painting and prepping rather than making adjustments to air movement systems.

Features directly addressing contamination on some systems have a nozzle system absorbing overspray. Nozzles absorbing overspray will prevent the dispersion of settled debris on the air nozzles of the air drying systems. Therefore, removing the possibility of overspray being released when air drying systems are turned on.

Features directly addressing contamination on some systems have a nozzle system absorbing overspray. Nozzles absorbing overspray will prevent the dispersion of settled debris on the air nozzles of the air drying systems. Therefore, removing the possibility of overspray being released when air drying systems are turned on.

To learn more about addressing issues read…